You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Overflow box holes and water level

- Thread starter Adamas

- Start date

It's a function of how many openings you have, how wide they are and how much flow is passing through them. Given that information the flow height can be calculated (in this case, the water level in the display tank). In engineering circles this type of flow is referred to as "orifice" flow.

I do this sort of thing on a larger scale for work and I've put together a spreadsheet to perform the calculation for our application (overflow box). If you (or anyone reading) is interested in taking a look at it and you have Excel send me an email...

I do this sort of thing on a larger scale for work and I've put together a spreadsheet to perform the calculation for our application (overflow box). If you (or anyone reading) is interested in taking a look at it and you have Excel send me an email...

Hi guys,

Just to accurate something, because some people didn't understand me well with overflow boxes.. I am talking about DIY overflow boxes inside the tank when you have a hole drilled in tank and not that external overflow boxes ..

I want to know exactly because I want my surface level to be under the 2 horizontal piece of glasses that support the tank at the top..

Thanks guys I really appreciate.

Just to accurate something, because some people didn't understand me well with overflow boxes.. I am talking about DIY overflow boxes inside the tank when you have a hole drilled in tank and not that external overflow boxes ..

I want to know exactly because I want my surface level to be under the 2 horizontal piece of glasses that support the tank at the top..

Thanks guys I really appreciate.

Well to know what it will be full blown simply place a 3g container or somthing under your intake tube running from your DYI box.

Start a syphon from another container see how long it takes to fill it up.

DO the math and you know what it is at full tilt.

The rest you can fine tune.

Start a syphon from another container see how long it takes to fill it up.

DO the math and you know what it is at full tilt.

The rest you can fine tune.

OK, lets' try this another way... :wink:

How many teeth will your overflow box have?

How wide will the gaps be between the teeth?

About how much flow do you expect to have going into the overflow box?

If you answer these questions I can give you some idea of how high the water will run in relation to the bottom of the teeth on the overflow box. Once you know that, you'll know where you should mount the overflow box in relation to your glass braces.

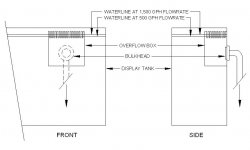

I've attached a quick sketch to illustrate. The following is an overflow box approximately 8.5" wide X 8" tall X 5" front-to-back with teeth that are 1/4" wide and 1.5" tall all around. I've shown the water level for 500 GPH (0.37" from bottom of teeth) and 1500 GPH (0.77" from bottom of teeth) flowrates as an example.

How many teeth will your overflow box have?

How wide will the gaps be between the teeth?

About how much flow do you expect to have going into the overflow box?

If you answer these questions I can give you some idea of how high the water will run in relation to the bottom of the teeth on the overflow box. Once you know that, you'll know where you should mount the overflow box in relation to your glass braces.

I've attached a quick sketch to illustrate. The following is an overflow box approximately 8.5" wide X 8" tall X 5" front-to-back with teeth that are 1/4" wide and 1.5" tall all around. I've shown the water level for 500 GPH (0.37" from bottom of teeth) and 1500 GPH (0.77" from bottom of teeth) flowrates as an example.

Attachments

OK, assuming the openings are a half cm wide (ie. 0.197") if you have 10 openings on each box and there are two boxes we have a total of 20 openings...

...so, that should result in the following approximate flow heights measured from the bottom of the teeth:

400 GPH flowrate = 0.54" (1.37 cm)

600 GPH flowrate = 0.70" (1.78 cm)

800 GPH flowrate = 0.85" (2.16 cm)

1000 GPH flowrate = 0.98" (2.49 cm)

That should give you some idea of where to mount the box in relation to the braces (assuming you get a reasonably accurate estimate of what your flowrate will be after plumbing losses).

HTH

...so, that should result in the following approximate flow heights measured from the bottom of the teeth:

400 GPH flowrate = 0.54" (1.37 cm)

600 GPH flowrate = 0.70" (1.78 cm)

800 GPH flowrate = 0.85" (2.16 cm)

1000 GPH flowrate = 0.98" (2.49 cm)

That should give you some idea of where to mount the box in relation to the braces (assuming you get a reasonably accurate estimate of what your flowrate will be after plumbing losses).

HTH

That will work fine. Ultimately, the water level will be determined by the flowrate provided by your return pump. If you find the water is running higher than you wanted, cut a few more slots in your overflow (or widen/deepen some of the existing ones if you prefer) or restrict the pump.

One comment - I recommend you size your drain plumbing and return pump so that the system can run on one of the two overflows if need be. Your overflow boxes go right to the top of the tank, so in the event that one of the drains got blocked you want to make sure the tank can't overflow.

HTH

One comment - I recommend you size your drain plumbing and return pump so that the system can run on one of the two overflows if need be. Your overflow boxes go right to the top of the tank, so in the event that one of the drains got blocked you want to make sure the tank can't overflow.

HTH

Why not just put a ball valve on both the intake and return so you can make the flow what ever you want from the get go?

You can also get the dimensions from some one who has an over flow box that handels what ever you want your flow to be and base it on that as well, with out all the complications. For instance I have a 600 GPH max over flow box I would be more than happy to give you the measure ments from.

I am a simple guy and like to make thing as simple as possible LOL!!!

You can also get the dimensions from some one who has an over flow box that handels what ever you want your flow to be and base it on that as well, with out all the complications. For instance I have a 600 GPH max over flow box I would be more than happy to give you the measure ments from.

I am a simple guy and like to make thing as simple as possible LOL!!!

His overflow box is already made and mounted in the tank and he's trying to predict how heigh the water line will run in his tank. The easiest way I know of to figure that out is to just do the math. Not very complicated at all really...

That said, IMO you should really plumb any return pump with valves/unions so it can be easily removed for cleaning, replacement, etc. and I do agree that the valve on the output side of the pump could also serve to help adjust the water level in the main tank.

That said, IMO you should really plumb any return pump with valves/unions so it can be easily removed for cleaning, replacement, etc. and I do agree that the valve on the output side of the pump could also serve to help adjust the water level in the main tank.

Fragmaster there is no place in there to make a ball valve and I think in this case its useless..

Like Chris said If I am not happy with the water surface level I can always widen or deepen some of the existing holes/slots that I have made to the box.

I hope it will work fine that method.

Like Chris said If I am not happy with the water surface level I can always widen or deepen some of the existing holes/slots that I have made to the box.

I hope it will work fine that method.

THats why you use a ball valve on the return side to make sure you dont run dry or low.

That way you can adjust it to a lower return rate if the pump is to strong, or simply buy a more powerfull pump if the rate is too Slow, and adjust or fine tune it with the ball valve.

A Mag 7 -9.5 will handle most aquariums with a wet dry system for up to a 600-800gph (respectively) over flow.

What we should also be asking is what size is his pump.

What size tube is he using, how many 90/45 deg angles as well as how many vertical and horizontal feet of return piping will there be.

IF you want a more true rate on both ends.

If your pump is too strong you can also restrict the flow by simply adding a second return point.

Which is IMHO the prefferd method for more water movement.

I was in mid edit while you were responding LOL!!! I didnt mean to type "both side's" or on the "intake side". TOO SLEEPY HERE! LOL!!

BUT.. There would be a place for a ball valve on the intake side if you used 3/4" ID hose to 3/4" pvc. Provided you only want around 500 gph.

That way you can adjust it to a lower return rate if the pump is to strong, or simply buy a more powerfull pump if the rate is too Slow, and adjust or fine tune it with the ball valve.

A Mag 7 -9.5 will handle most aquariums with a wet dry system for up to a 600-800gph (respectively) over flow.

What we should also be asking is what size is his pump.

What size tube is he using, how many 90/45 deg angles as well as how many vertical and horizontal feet of return piping will there be.

IF you want a more true rate on both ends.

If your pump is too strong you can also restrict the flow by simply adding a second return point.

Which is IMHO the prefferd method for more water movement.

I was in mid edit while you were responding LOL!!! I didnt mean to type "both side's" or on the "intake side". TOO SLEEPY HERE! LOL!!

BUT.. There would be a place for a ball valve on the intake side if you used 3/4" ID hose to 3/4" pvc. Provided you only want around 500 gph.

I'm not really sure what you're trying to get at here. There's no need to restrict the intake of the return pump and it's definitely not good practice as it can cause cavitation.FragMaster":1qyipiez said:THats why you use a ball valve on the return side to make sure you dont run dry or low.

That way you can adjust it to a lower return rate if the pump is to strong, or simply buy a more powerfull pump if the rate is too Slow, and adjust or fine tune it with the ball valve.

At any rate, in this case you can't really use a valve to raise the water level in the display tank much. You could restrict the drain lines with valves, but all that will do is raise the water inside the overflow boxes. It won't effect the level in the main tank much unless you restrict the drains so severly that the water level backs up above the overflow boxes which pretty much defeats the purpose of an overflow box. :wink:

To me it makes more sense to do a little math first and get an idea of what you're dealing with so you can minimize the chances of having to change stuff later like box height, plumbing and pumps. That's all we're really doing here...

Yes, that information would be needed to estimate the flowrate, and as we mentioned earlier in the thread, flowrate will play a role in what the running water level is in the display tank.FragMaster":1qyipiez said:What we should also be asking is what size is his pump. What size tube is he using, how many 90/45 deg angles as well as how many vertical and horizontal feet of return piping will there be.

Actually adding another discharge point will decrease the amount of restriction on the pump resulting in more flow, not less. It will decrease velocity at each outlet, but will result in a slight increase in overall flow volume.FragMaster":1qyipiez said:If your pump is too strong you can also restrict the flow by simply adding a second return point.

Which is IMHO the prefferd method for more water movement.

No the added 90 degree elbows WILL DECREASE flow by baffeling it and reducing head hieght.

And the ball valve would be AFTER the pump not before. How the heck would you go about putting a ball valve on the intake of the pump? Unless its out side hte sump there is no room for it?

Thats why I said "return".

I have used ball valves on BOTH sides before with no cavetation and no adverse effects of any kind. (not on the intake to the pump, on the return line to the tank, and I used 3/4" pvc not 1 1/4" hose from my box.)

Its called working with what you have when you dont have the money for a stronger pump! LOL! Just takes a little patience and a magic marker to mark water levels.

And the ball valve would be AFTER the pump not before. How the heck would you go about putting a ball valve on the intake of the pump? Unless its out side hte sump there is no room for it?

Thats why I said "return".

I have used ball valves on BOTH sides before with no cavetation and no adverse effects of any kind. (not on the intake to the pump, on the return line to the tank, and I used 3/4" pvc not 1 1/4" hose from my box.)

Its called working with what you have when you dont have the money for a stronger pump! LOL! Just takes a little patience and a magic marker to mark water levels.