is the noise from the splash or the gurgling? how is the sump currently configured?

i recently

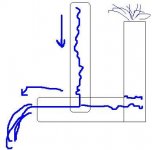

saw one setup where the inflow was 'contained' within a 4" pvc coupling with outflows drilled throughout below the waterline. this somewhat muffled the splash and gurgling with a conventional pipe inflow.

i've tee'd off inflows somewhat like you're suggesting, like len says though, the air will likely get pushed along with the waterflow. you can mitigate this slightly by using an oddball tee, i.e. 2" x 2" x 1" tee. that should limit some of the gurgling/splash to the inside of the tee.

adjusting the endpoint/outflow to straddle the waterline will further limit noise as there will be no cascade/waterfall in that position.

you could also just turn the tee so that one side flows downward and the other is pointed up as you planned in that design. (i'd still use an oddball tee though) but you could also cap the "up end" with a drilled hole (the escaping air only needs a small opening) to add an addt'l layer of muffling.

i've also taken to placing a cinchable filter bag over sump inflows to further muffle noise and limit splash.

i'm not too keen with the valve suggestion though as any slight clogging could create an issue. hence, i always try to use as large a pipe for the inflow as possible. hth