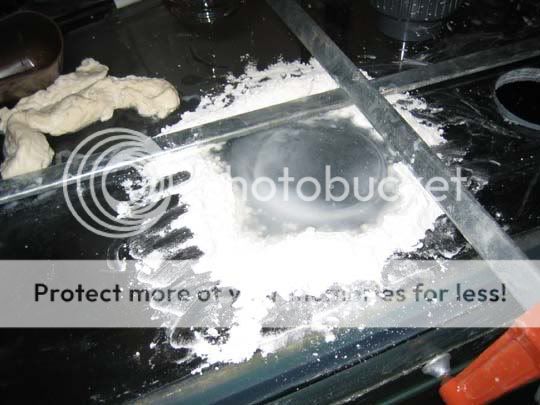

I was able to cut the holes for the bulkheads in my sump. I needed to cut two holes, one for a 2 inch bulkhead and the other for a 1.5 inch bulkhead. After allot of research on how to make the cuts, I decided to make a dam so that the hole could be cut in some water which will help keep the saw and glass cool.

I had wanted to make a dam out of clay but I forgot to pick it up when I was out of the house, so I took some flour and water and made some dough. The dough worked pretty good, but for the second cut I just made a dam out of some flour which believe it or not worked allot better.

This is the bit I used to cut the hole for the 1.5 inch bulkhead, it was fairly inexpensive running me about $5. It was shipped straight from Hong Kong.

The problem with getting the hole started is that the bit wants to "walk". I used two clamps to act as guides while I got the hole started.

I went real slow, and didn't let my drill pick up too much speed. Each hole took me at least 10 minutes to cut.

After that was done I screwed on the bulkheads and put the sump into place. This is the finished product. Look at a that starphire...it really makes a difference.

I was able to make allot of progress this weekend. I sheetrocked the area behind the sump, finished of the wall and got two coats of paint on it. I got the sump into place, reinforced the stand a bit and I am starting to fill the display tank with water. I figure it will take almost 4 days to get the sump and display tank filled with RO/DI water. Once it is full, I will add salt and get all the pumps moving to mix it up. Now I just need to finish off the plumbing.