Hello Everybody,

I just set up a 72 Bow Front. Was Running great and plumbing set up was awesome. But somehow. I ended up with a STUPID LEAK in the return line :irked:, small one like 1/2 a drip.

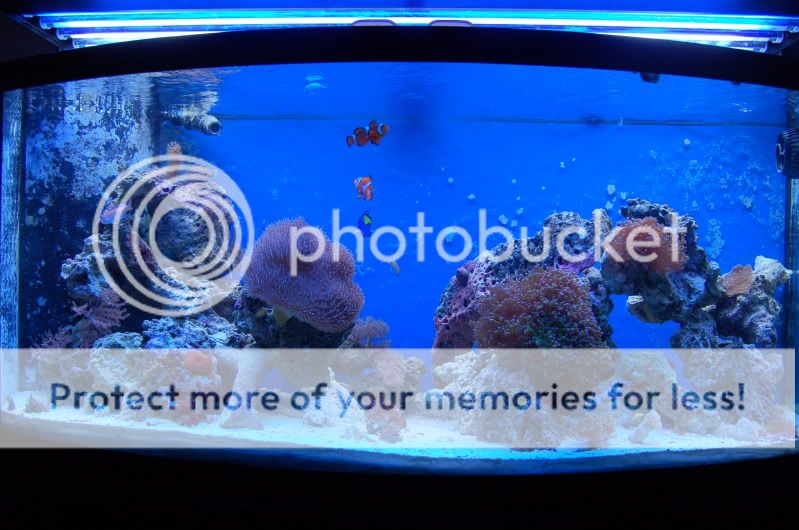

That's how it was before the silicone. If you look to the right that little gap between the hose adaptor and pvc pipe is where the leak is. The drain is fine.

So to remedy the problem, I tried to use my ugly craftsmanship to fix it. I have big hands so it was hard. The drip is only coming from the front portion because the nylon tape came off a little bit of the fitting.

I put Aquarium Silicone under it to fill the gap... still leaked. I put PVC Glue on top of the silicone... less leak. Then I put the bathroom silicone gel. A little better but coming through

HELP ME PLEASE

I just set up a 72 Bow Front. Was Running great and plumbing set up was awesome. But somehow. I ended up with a STUPID LEAK in the return line :irked:, small one like 1/2 a drip.

That's how it was before the silicone. If you look to the right that little gap between the hose adaptor and pvc pipe is where the leak is. The drain is fine.

So to remedy the problem, I tried to use my ugly craftsmanship to fix it. I have big hands so it was hard. The drip is only coming from the front portion because the nylon tape came off a little bit of the fitting.

I put Aquarium Silicone under it to fill the gap... still leaked. I put PVC Glue on top of the silicone... less leak. Then I put the bathroom silicone gel. A little better but coming through

HELP ME PLEASE