I spent a while getting my

ATO set up. For me this was actually one of the most important parts of the tank. Being able to never have to worry about water, in and out of the tank, is a good thing IMO.

For my top-off and water changes I am using what was an Aqua-FX 4 stage RO/DI unit. I say was, because at this point I have replaced about everything in it so it's not really the same anymore.

Due to my ro/di unit sitting unused for almost a year, I needed to replace all of the canisters, so I am using a new 75gpd membrane, sediment, carbon and DI filters. I also bought an inline TDS meter. I never had one, it's a nice thing to have. My TDS is 157 in and 0 out.

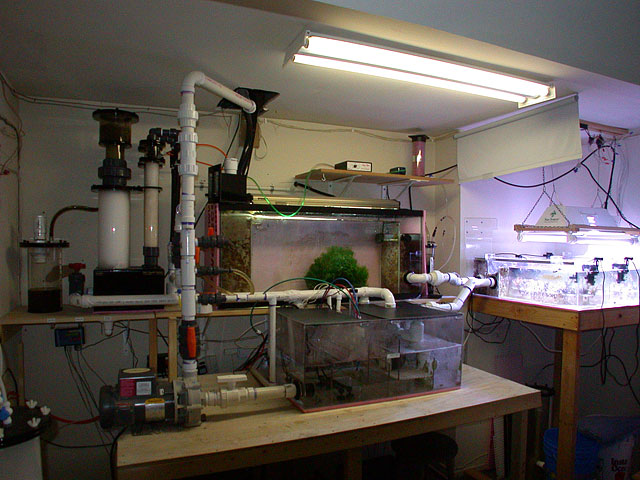

I set up a 55 gallon Rubbermaid plastic container the same as with my old tank. The tank is used for all RO/DI storage. This time I used a low/high float switch, from top-off.com, that I bought at one of the MACNAs a while ago.

It works real well. When the water drops to a set level it turns on a polypropylene solenoid valve I got from mcmaster.com I think it is PN#7877K23. That turns on my ro/di until the top level switch is reached and then turns off. There is a redundant switch above as a safety switch. So really there is no worries about the unit not switching off.

Once I got that all set up I went to work on getting the water into the sump. I am using a large polypropylene tank. Which works well as a sump but I don't have anything to attach stuff to. I drilled out a 1/2" bulkhead and attached a 1/2" PVC pipe so I can attache some float switches to it.

On my last tank I had float switched on a piece of PVC that was cabled tied down. The cables would always move just a little, once in a while, to change the level a bit. This time I wanted to make it was a bit more solid.

I decided to use three float switches.

1) A low level that would sense if the water level in the sump became too low as to allow the main pump to suck in air. If the low level trips the main pump will get shut down.

2) A high level. That will shut down the power to the top-off pump in case the top-off float were to stick.

3) Top-off level switch. Just a standard float kicking off a pump in the ro/di reservoir to replace water that evaporates.

First I cut out a piece of acrylic and used a tap to make a hole to attach the float switch as well as a 1/4" nylon screw. Then I bent it to a 90d angle.

Attached the float, the screw, and two cable ties to keep it from shifting.

Then I attached them to the pipe. I left everything in place for a day or so to make sure the positions were good. then I pulled the pipe and tapped three holes so I could screw the floats in. Now when I take the floats off to clean them I can be sure I am putting them back in the same place.

Next I needed to hook up the float switches to my Apex. The controller can take two switches on it's own. On the old tank I had the floats wired into a terminal block, but it was a pain if I need to take them off. So I built a nice little enclosure.

First take the cable and break out all the wires to their terminals on the block.

Next drill some holes in the box to mount hardware to plug the floats switched into. Then put in the terminal block and wires it all up.

Close it up and I'm all done. Now it will be much easier to add and remove the float switches.

Mounted everything up and tested it. So far it works great.When the top-off float kicks in everything works as it should, the water levels doesn't seem to vary more than 1/2" in the sump. So you really never see a sump level change at all. If the low level float trips, the Apex shuts off the main pump, trips an audible alarm in the house and send me a page and emails a few different accounts telling me the low level alarm tripped and the main pump is on.

If the high level alarm trips the power to the top-off is cut, an alarm sounds in the house, and I get paged and emails sent as well.

Ok, believe it or not this took me like three days to do. :lol: