Long past due hood pics. Just finished it up today pretty much. Its built the same way as the stand, with a ply skeleton and a veneered mdf shell. Lemme know if somethings wrong, or im missing things. I had alot on my mind during this and had to rush the design a little. As well as slight problems with other things.

I half worked on this and the rest was finished up by one of my workers who did an amazing job with panel matching (had some problems with lack of enough material the correct sizes) and putting the finishing touches on.

The hood measures 15" high for the outside dimension. That gives me enough room inside to adjust the MH heights and gives me the amount of lighting I want with the depth of the tank. The top of the hood will stay as is. The complete tank stands at roughly 82-84 inches, and i will never see the top. Plus, i ran out of material and its not cheap.

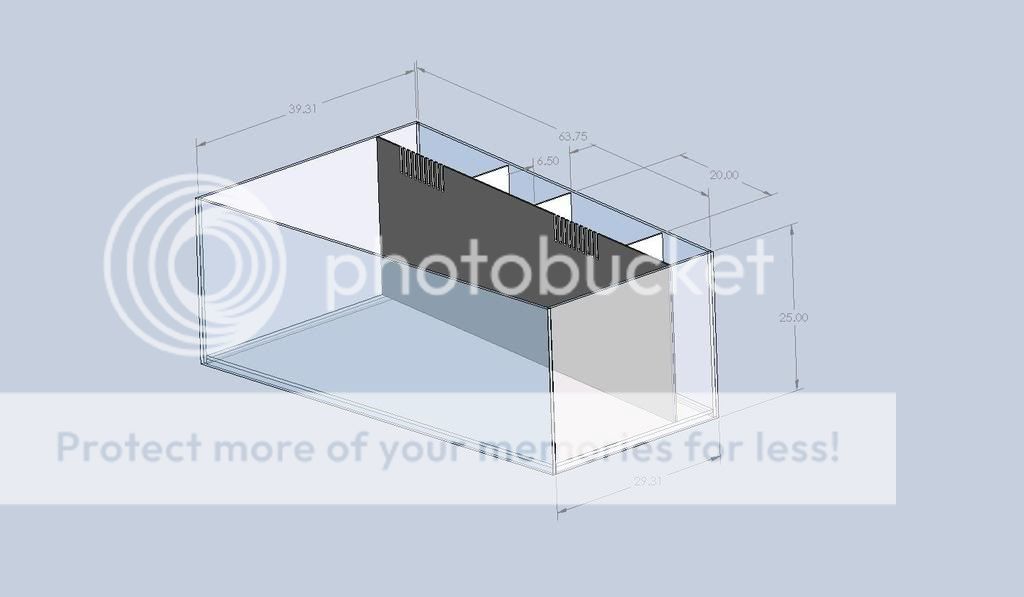

The skeleton and you can see the area for the bulk of my electrical work. The area will be vented with fans into the hood itself (still desciding, might go into the back and out as to not transfer extra heat into the hood) on the slanted piece on the back. As far as venting for the hood as a whole, im still working on the intake, but the exhaust fans will be on the right side of the hood behind a brass grill once i find one laying around that fits. 3x 120mm PC fans i think im going to use for the hood, and i can fit 1-2 80mm PM fans for the electric compartment.

Inside of the electrical compartment is flat on the inside of the hood, with an added piece for the angled end. Done for structure and because i didn't have time to go that extra mile of wierd cuts and aligning. Now that im looking back at it, the angled piece turns useless, and really has no purpose if im going to vent it behind the hood.

Btw, the front pieces of ply spanning the doors on the bottom will be cut out and removed. They are there to add some structure and alignment/spacing during the build process.

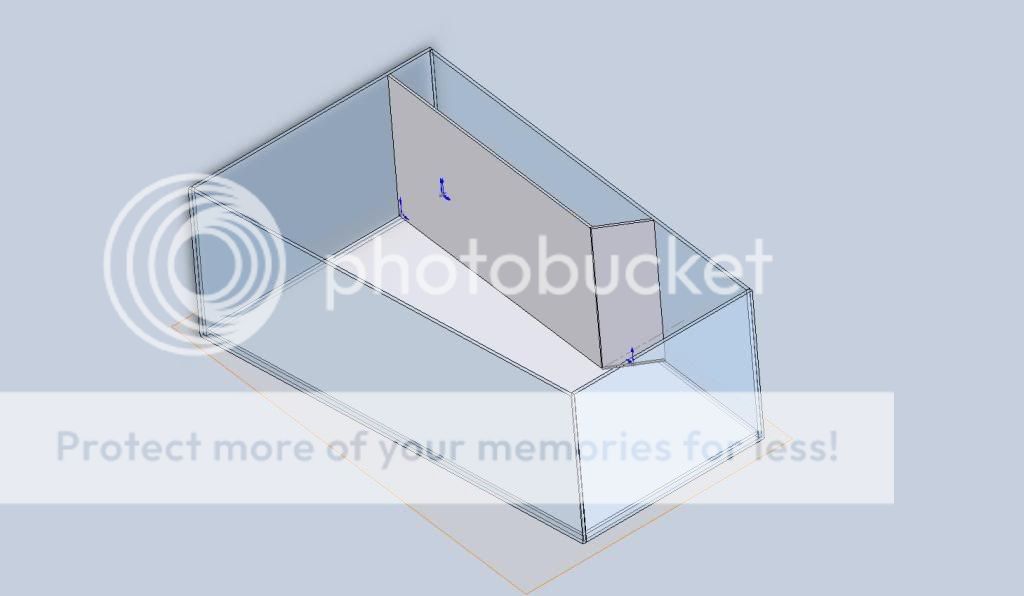

Pics on the panel going over the electric. Im going to install guides for the corner that is removable as ill open it rarely and don't need a fancy hinge. The whole side slides out, and was done to reduce break lines in the corner and side of the hood if i made it just enough to cover it. if that makes sense.

Doors are set on Soss invisible hinges and im still deciding on using those magentic spring push latches and where they will be mounted and if they will work correctly.

I took an easy way out as far as the hood sits on the tank rim due to a screw up when making the rim molding. So as it stands currently, ill be just placing the hood on the top rim, which has a flat surface, and tapping/screwing into the rim itself in 5-6 places then secure the hood with nylon screws. I made a 1" lip on the inside of the hood to allow that. Ill take off the hood maybe 2x a year max, and would need 2 people. So, its fine and i could deal with this descision. Ill be routing out part of the rim under the doors to provide a water catch when doing things inside the tank so water doesn't get between the hood and tank as much.

Think thats it for now. Lemme know your thoughts and ideas. Anything is helpful and stuff still can be changed within reason. :tub: