- Location

- Greenpoint Brooklyn, NY

RO tubing split huh. Your making me think twice now about running it that long. Actually running it any length. But then i have to worry about the RO tubes running into my RO unit from the water main.

As far as ....

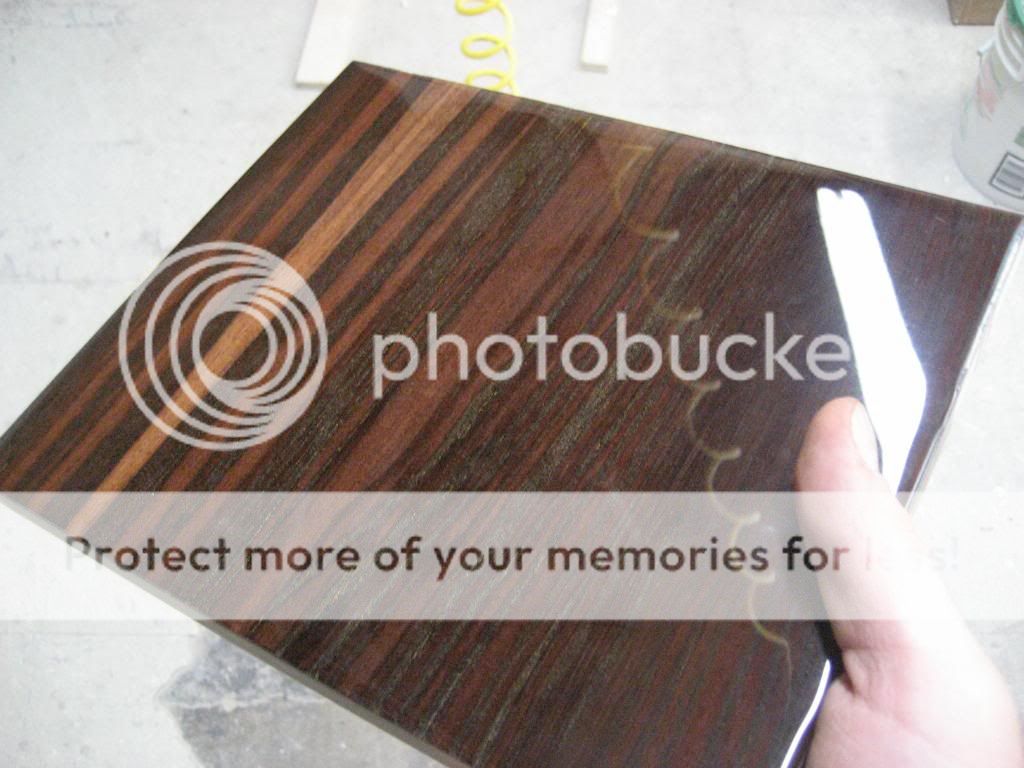

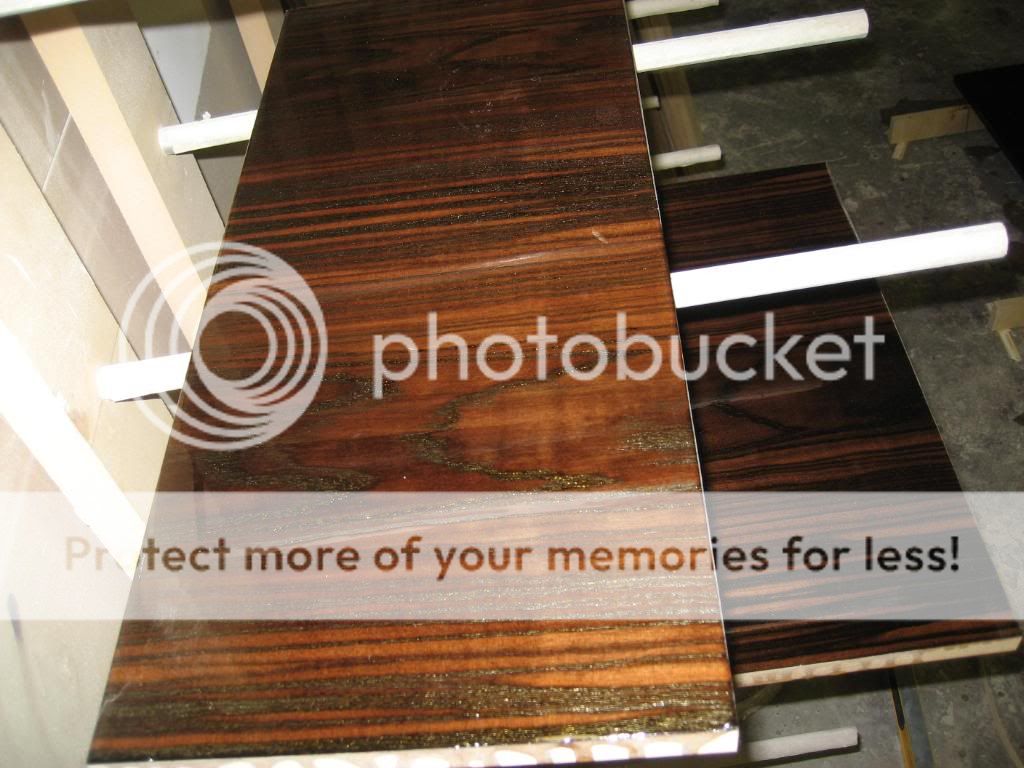

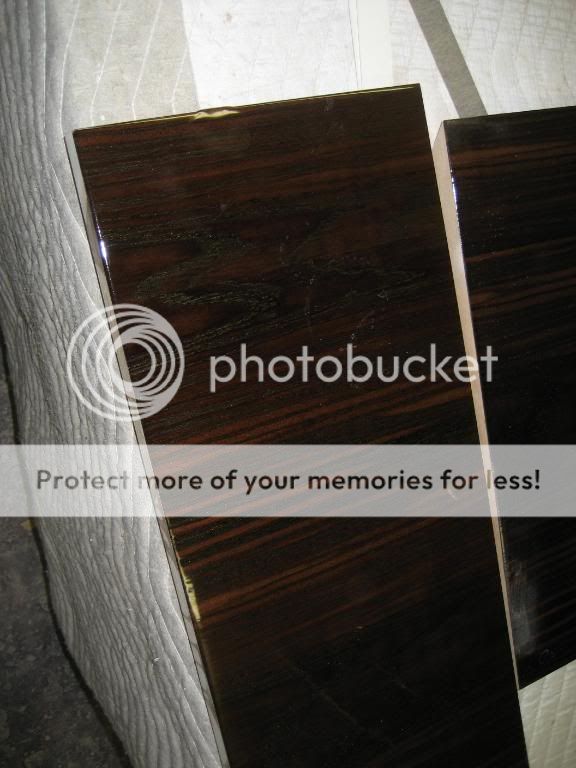

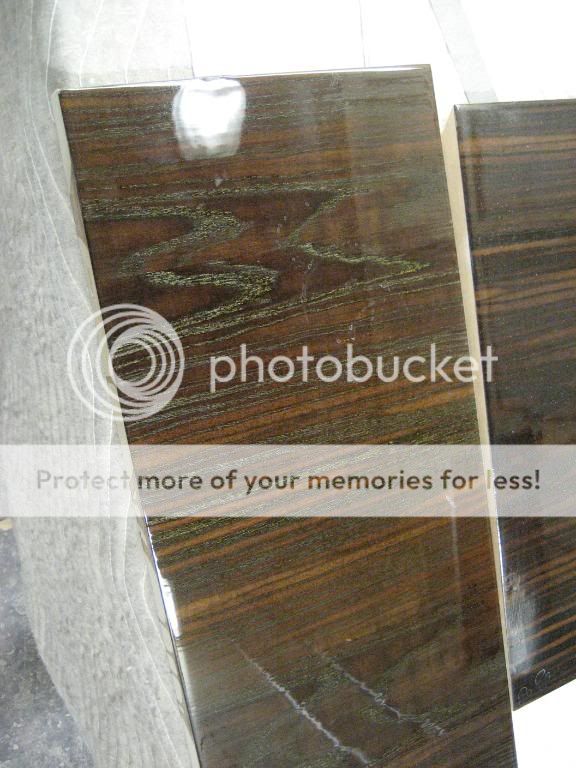

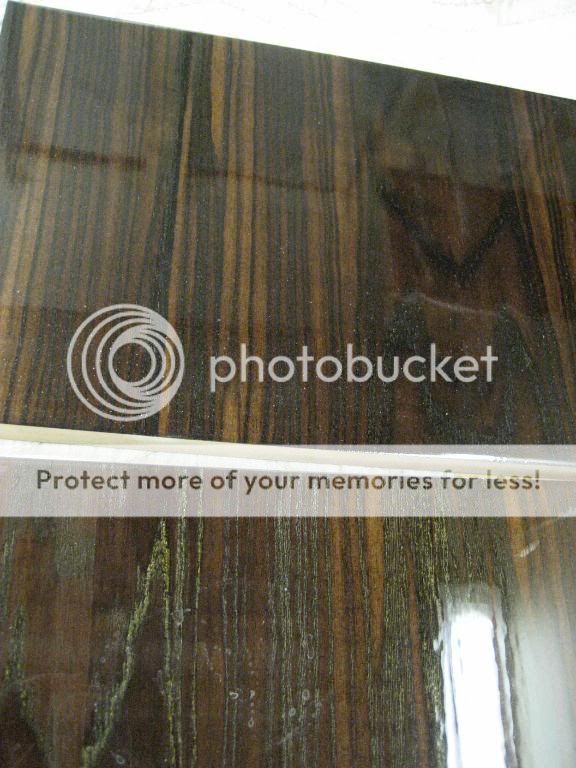

goes, its things like that that some people don't understand when it comes to better quality hand made things compared to factory run objects as far as pricing goes. When i get emails asking about pricing of cabinetry and stuff people start to compare it to ikea or lower end millwork companies. If thats the price range for what your looking for then thats where you get it. Alot of the factory built millwork and cabinetry is very nice but you get what you pay for when it comes to how its built and how long its gonna last you. But there is a big difference between the higher priced bedroom sets or kitchens available and what you can get from the discount area in ikea.

Also, People don't take into consideration the thought, time and quality of products used in making the better cabinetry/furniture/millwork and why it stands apart from the rest out there. Its hard to realize it as everything looks easy in theory and on paper.

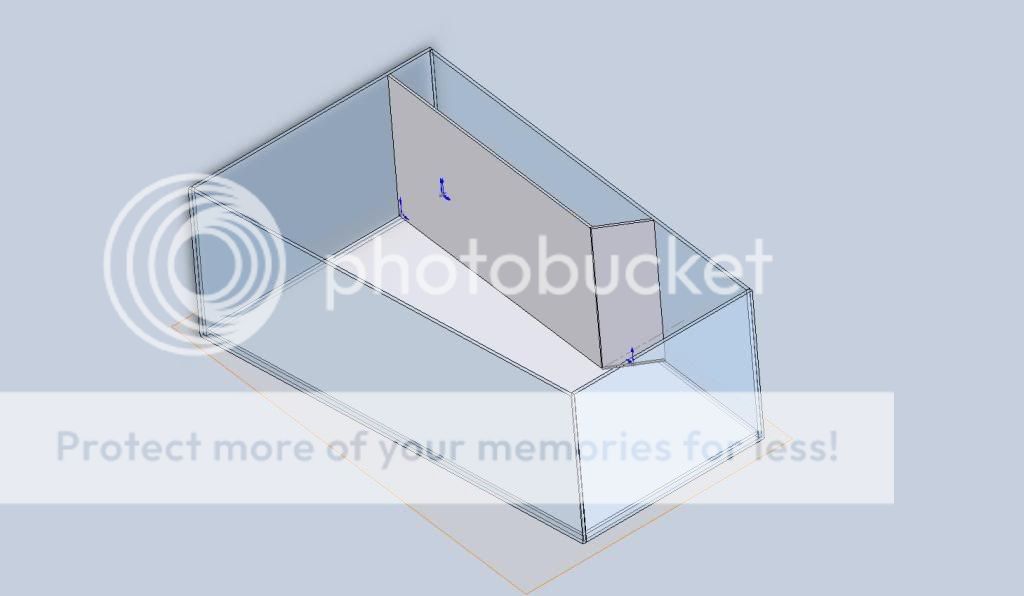

Small tanks i priced for people i can't cut as low as glasscages and the other custom places. They are ordering everything in bulk and doing alot of the glasswork in house and i can tell you that pricing differs by more than half before profit comes into play. I was quoted $3000 by one glass place for starfire glass on my current tank. The glass place i do alot of buisness with gave me materials + work time without profit and the same glass came out to around $900.

As far as ....

Time adds up, this project lets people see why custom is worth the cost

goes, its things like that that some people don't understand when it comes to better quality hand made things compared to factory run objects as far as pricing goes. When i get emails asking about pricing of cabinetry and stuff people start to compare it to ikea or lower end millwork companies. If thats the price range for what your looking for then thats where you get it. Alot of the factory built millwork and cabinetry is very nice but you get what you pay for when it comes to how its built and how long its gonna last you. But there is a big difference between the higher priced bedroom sets or kitchens available and what you can get from the discount area in ikea.

Also, People don't take into consideration the thought, time and quality of products used in making the better cabinetry/furniture/millwork and why it stands apart from the rest out there. Its hard to realize it as everything looks easy in theory and on paper.

Small tanks i priced for people i can't cut as low as glasscages and the other custom places. They are ordering everything in bulk and doing alot of the glasswork in house and i can tell you that pricing differs by more than half before profit comes into play. I was quoted $3000 by one glass place for starfire glass on my current tank. The glass place i do alot of buisness with gave me materials + work time without profit and the same glass came out to around $900.